OEM Equipment Parts: Ensuring Optimum Performance and Durability

OEM Equipment Parts: Ensuring Optimum Performance and Durability

Blog Article

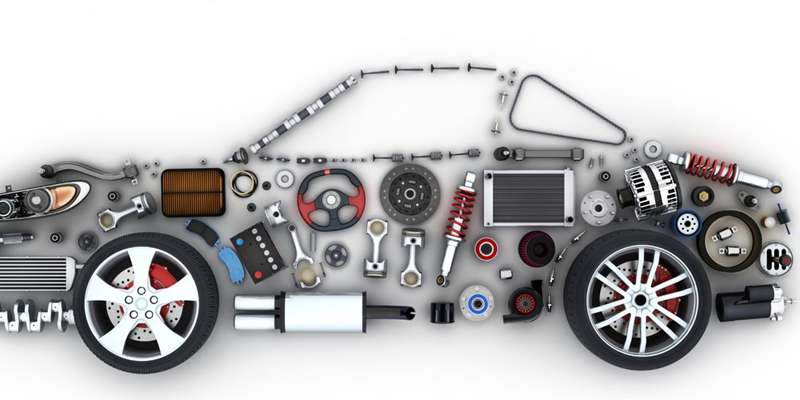

The Advantages and Drawbacks of Choosing OEM Construction Parts Over New Components for Your Devices

When it comes to fixing and maintaining equipment, the decision in between deciding for original devices maker (OEM) construction parts versus brand-new parts is a vital consideration for lots of businesses. While OEM parts are made to satisfy the particular needs of the devices and are typically connected with a higher degree of high quality and compatibility, there are likewise downsides to be considered, such as prospective price effects and availability concerns.

High Quality and Compatibility Perks

When thinking about the top quality and compatibility advantages of OEM construction parts versus brand-new parts, it is vital to review their precision design and seamless assimilation abilities. OEM building and construction parts, being initial equipment produced by the same company that created the devices itself, are designed to precise requirements.

Greater Expense Factors To Consider

Given the superior high quality and compatibility advantages of OEM building and construction components over repairs, it is important to now resolve the aspect of higher price considerations in the decision-making process. While OEM parts are recognized for their specific fit and high performance, they often come at a higher cost factor compared to aftermarket options. The preliminary investment in OEM parts might seem extra expensive, yet over time, they can show to be a lot more cost-effective as a result of their toughness and reliability.

One crucial factor to think about when examining the greater expense of OEM building components is the prospective cost savings in terms of reduced repair and maintenance expenses. OEM components are crafted to satisfy the specific demands of the tools, which can result in less failures and less downtime. This can convert into significant expense savings for devices owners in terms of lower fixing and substitute prices over the lifespan of the equipment.

In addition, spending in OEM parts can also add to keeping the resale value of the tools. Oem Construction Parts. Ultimately, while the greater price of OEM building components might require a bigger upfront investment, the long-term benefits in terms of cost, efficiency, and integrity financial savings make them a beneficial and sensible option for equipment proprietors looking to maximize the value of their investments.

Integrity and Warranty Insurance Coverage

In assessing the option in between OEM building components and new components, an important element to consider is the level of dependability and guarantee coverage given. OEM construction parts, being manufactured by the initial equipment producer, are made to fulfill the exact specifications of the equipment, making sure a high level of integrity.

On the various other hand, new components may not constantly supply the very same level of integrity as OEM parts, as they might not have actually been specifically designed for the tools in inquiry. When taking into consideration dependability and warranty protection, deciding for OEM construction parts might offer an extra safe and reputable solution for devices maintenance and durability.

Performance and Durability Enhancements

Having developed the importance of dependability and service warranty protection in the selection in between OEM building and construction parts and brand-new components, the focus currently changes towards reviewing exactly how these parts add to performance and durability enhancements. OEM construction parts are crafted to specific requirements, making sure seamless assimilation and ideal performance within the devices. This precision leads to improved general effectiveness and performance, as the parts are made to function harmoniously with the machinery they are intended for.

Additionally, OEM parts commonly undertake strenuous testing to fulfill sector requirements and maker needs, ensuring a higher degree of high quality compared to generic options. This exceptional top quality converts into boosted resilience and longevity for the equipment, minimizing the risk of unexpected failures and expensive repair services. By utilizing OEM construction components, tools owners can experience enhanced performance, extended lifespan, and lessened downtime, ultimately leading to enhanced functional efficiency and cost-effectiveness over time.

Potential Limited Availability Issues

When depending on OEM construction components for equipment repair and maintenance, one significant downside that can occur is the possible limited availability of these components. Due to elements such as manufacturing timetables, supply chain disruptions, or the discontinuation of specific components by producers, there might be circumstances where OEM parts end up being scarce or also outdated. This scarcity can result in hold-ups in devices servicing, extended downtime, and increased prices connected with sourcing different options.

Minimal availability of OEM construction components can additionally interfere with the efficiency of upkeep teams, as they may need to invest extra effort and time browsing for suitable substitutes or waiting on back-ordered components to show up. In situations where details OEM components are important for optimum tools efficiency or security compliance, the unavailability of these components can position major functional threats. To alleviate these challenges, equipment supervisors should keep clear interaction with distributors, explore options for equipping essential components beforehand, and think about different remedies or aftermarket components when OEM alternatives are scarce.

Conclusion

To conclude, when considering whether to pick OEM building parts over brand-new parts for tools, it is necessary to consider the advantages of top quality, compatibility, reliability, efficiency, and long life against the drawbacks of greater price Continued and potential limited schedule. Inevitably, the decision must be based upon the certain requirements and top priorities of the equipment owner, in addition to the value of guarantee protection in making sure long-term satisfaction and functional performance.

When it comes to maintaining and fixing tools, the decision between opting for original tools producer (OEM) building and construction parts versus new parts is a vital factor to consider for lots of businesses.Given the superior high quality and compatibility advantages of OEM construction components over brand-new components, it is important to now attend to the element of greater cost factors to consider in the decision-making procedure.On the various other hand, new parts might not constantly offer the same level of dependability as OEM components, as they may not have actually been particularly developed for the equipment in question.When depending on OEM building components for devices maintenance and repairs, one substantial drawback that can emerge is the potential minimal accessibility of these parts. To alleviate these challenges, tools managers need to maintain clear interaction with providers, discover options for equipping critical parts in advance, and take into consideration try this website alternate remedies or aftermarket parts when OEM choices are scarce.

Report this page